PGF/YDL Can Filler And Seamer |

| Capacity: |

max 72.000 bph |

| BRIEF INTRODUCTION |

The short tube filler or volumetric can filler in hygienic design is used to fill beer or carbonated soft drinks in aluminum cans.

The filler is blocked with a seamer and is driven by frequency-controlled motors. The cans are supplied to the filler in handling parts, designed for quick changeover and made from high wear resistant plastic material. Both cold fill and warm fill up to 15°C

is possible. The fill height is either controlled by vent tubes or volumetric control to ensure high fill level accuracy. All parameters can be easily adjusted on the HMI. The filer is equipped with oxygen measurement and fully automatic CIP and COP process.

All parts of the filler are designed for easy cleaning and sterilization. |

| OPERATION SAFTY |

1.Protection doors surrounding the machine, alternative by filling room.

|

| 2.Auto stop at all doors and windows. |

| MACHINE BENEFITS |

| 1.Hygienic design with automated CIP and COP. |

| 2.Circular type ring bowl in sanitary design without dead spaces. |

| 3.Motorized height adjustment of filler bowl to adapt the filler to different SKUs. |

| 4.Automatic filling speed control according to infeed/discharge product flow. The infeed is automatically stopped if the flow of empty cans is interrupted. Filling speed and can counter are displayed on the HMI. |

| 5.Reliable plastic infeed star wheels for quick change over and fast release. |

| 6.Coupling joint connection between filler and the seamer to ensure synchronization. |

| 7.Dissolved oxygen measurement and control. |

| 8.Hygienic central supply pipe to avoid cross contamination between product (CO2/CIP) and operation gas, no fluid or gas accumulation for easy cleaning. |

| 9.Stable operation, filling volume is pre-set at the HMI for high filling accuracy. Minimized product loss. |

| 10.Microbiological safe guiding parts with self-contained star wheels, open guiding curves and streamline support parts to eliminate dead spaces,ensuring complete cleaning and sterilization of all outside surfaces. |

| 11.Glass observation window in product supply pipe. |

| 12.Auto CIP dummy cups as option. |

| 13.Microbiological safe guiding parts with self-contained star wheels, open guiding curves and streamline support parts to eliminate dead spaces to ensure complete cleaning and sterilization of all outside surfaces. |

| 14.Glass observation window in product supply pipe. |

|

15.Auto CIP dummy cups as option. |

| SUSTAINABILITY |

| 1.80% reduction in water consumption. Additional water saving with water blow off and collection at the machine discharge. |

| 2.40% reduction of steam consumption with insulated piping and housing. Independent hot water tank with a single PHE. |

| 3.Optimized pump module selection in class IE3 or above with power saving motors as option. |

| 4. Machine structure in stainless steel and spraying nozzles in clip on design for minimized maintenance. |

| PRODUCTION CAPACITY |

| Ringbowl diameter |

Number of valves |

Capacity per hour |

| 1,600 |

32 |

6.000 to 15.000 |

| 2,000 |

40 or 50 |

15.000 to 36.000 |

| 2,400 |

60 |

27.000 to 40.000 |

| 2,166 |

76 |

32.000 to 50.000 |

| 2,622 |

92 |

43.000 to 60.000 |

| 3,078 |

108 |

51.000 to 72.000 |

| 3,648 |

128 |

60.000 to 90.000 |

| 4,104 |

144 |

90.000 to 120.000 |

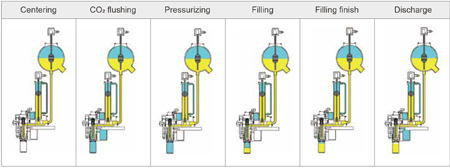

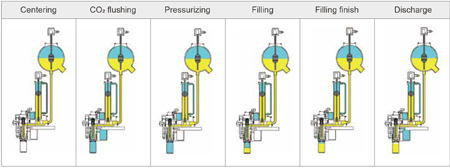

| FILLING PHASES |

|

| FILLING TECHNOLOGY |

1.PGF: Mechanical filler with vent tubes and cam control.

|

| 2.YDL: Volumetric filler with measuring cylinder for filling volume control with deviation within ±1ml. |

| |

0086-571-87978016

0086-571-87978016 info@youngsunpack.com

info@youngsunpack.com